Visions

for the

Future of Manufacturing

Confectionary and engineering

ChocoVisions

Driven by innovations

Innovations! Since 1949, we have always been up-to-date and looking to meet every new challenge. Many customers involve us early as an innovation partner into their process optimisation – e.g. product design to increase production output. Why do they do that? Because we see the apparently impossible as a challenge.

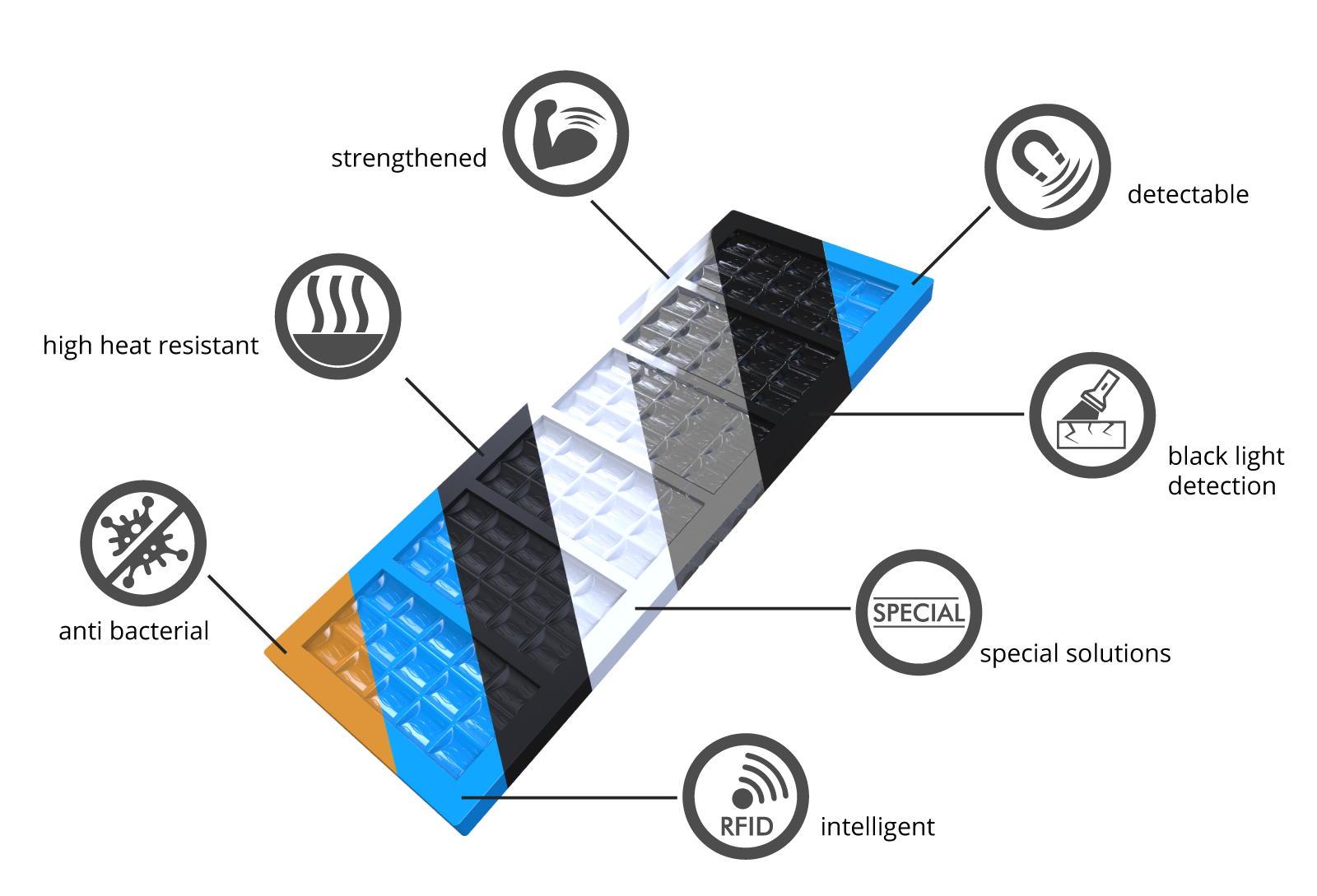

Cost of ownership for our customers is always the focus of our involvement. Innovative overall projects minimise downtime and maximise the use of your production capacity. Recent examples using RFID, FEA calculations, MouldFlow analysis, simulations of mechanical influences on production and fatigue durability studies with field tests show that we consider your processes as a whole.

„A really good idea can be seen in the fact that their realization seemed excluded from the outset“

Reinforced plastics:

Support systems meeting demanding mechanical requirements can be made from robust plastics with a correspondingly innovative design as an alternative to metal.Metal-detectable moulds:

In the interests of food safety, we presented the first chocolate mould made of metal-detectable material, but without metal content in 2007.RFID:

Since 2003, agathon has been equipping moulds with RFID chips/ electronic data carriers for various applications:

- mould identification/tracking

- control of the dosing unit

- control of the washing process, etc.

To run with moulds for new products, we have developed the first prototypes of RFID chips complete with a temperature sensor. This offers the possibility of obtaining important real time information on the temperatures experienced by the moulds as they run through the plant with important implications for chocolate crystallization.

Special developments:

If you have a specialist, non-standard application or production process, we will support you in every way, including ‘on site’ visits. Our team will custom-develop components suitable for your individual requirements and remain confidential.

Black light detection:

A new material makes tiny cracks visible under Black Light, which enables full wear Transparency and an improved Food Safety.

Moulds with antibacterial surface:

Our R&D department has already successfully produced examples of chocolate moulds with an antibacterial surface and tested for mechanical load. The next goal is conformance with the International Food Standard.

Am Kruppwald 3

46238 Bottrop

Germany

This email address is being protected from spambots. You need JavaScript enabled to view it.